Local is the Answer

North Mississippi is blessed with abundant forests that are home to a great variety of hardwoods. Embracing these native hardwoods not only supports sustainable forestry practices but also strengthens the local economy and preserves our Mississippi heritage.

The sustainability of using local hardwoods cannot be overstated. When woodworkers and craftsmen source wood from nearby forests, transportation distances are dramatically reduced compared to materials shipped from out of state or overseas. Beyond transportation, responsible forest management is at the core of sustainable hardwood use. Practices such as selective harvesting, replanting native tree species, and protecting wildlife habitats help ensure that forests remain vibrant and productive for generations. When consumers choose furniture made from locally sourced hardwoods, they help incentivize these responsible practices, encouraging landowners and woodworkers alike to steward forest ecosystems thoughtfully.

Economic benefits of using local hardwoods extend directly into the heart of Mississippi’s communities. Choosing lumber milled in Yalobusha County means keeping money within the local economy. Instead of dollars flowing out to distant suppliers or international manufacturers, your money can circulate among Mississippi’s sawyers, woodworkers, craftsmen, and retailers. For North Mississippi where economic opportunities can be limited, keeping those dollars in Coffeeville, Water Valley, Oxford, and Batesville fosters small business growth and creates more resilient economic networks.

Culturally, craftsmanship rooted in local materials also nurtures our identity. Mississippi has a deep tradition of skilled woodworking and folk art. Furniture crafted from native hardwoods reflects not just utility, but also the character of the landscape and the hands that shaped it. This cultural resonance has both aesthetic and emotional value; it deepens connections between people and the place we call home.

For those of us lucky enough to call North Mississippi home, using local hardwoods can offer superior quality. Hardwoods like white oak, cherry, pecan, and hickory are durable, strong, and age gracefully, making them ideal for heirloom furniture that stands the test of time. When crafted with skill, such pieces surpass mass-produced alternatives in both performance and longevity, reducing the need for frequent replacements and further supporting sustainable consumption patterns.

Whatever the project, if local hardwoods are a possibility, it is worth considering them.

Red or White Oak?

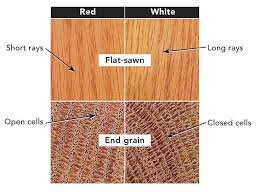

Red oaks and white oaks are found throughout the forests of North Mississippi. Though similar, the two groups differ in appearance, wood anatomy, and lumber uses.

You can tell them apart most easily by the leaves and acorns.

Red oaks have pointed leaf lobes with tiny bristle tips, and their acorns take two growing seasons to mature. White oaks have rounded leaf lobes without bristles, and their acorns mature in one season. The bark can help too: white oak bark is often lighter and flaky, while red oak bark is darker with long vertical ridges.

When it comes to how the two groups are used, you may think the color is the main difference. While the different species do have different coloring and distinct appearances in their ray fleck, the wood structure is the biggest industrial difference.

Red oak has open pores that run through the grain, making it porous and less resistant to moisture and decay.

White oak has closed pores (often plugged with tyloses), making it water-tight and very rot resistant.

Because of this, red oak lumber is widely used for interior flooring, furniture, cabinets, millwork, and trim. White oak lumber is used where strength and moisture resistance matter: barrels and wine casks, boat building, exterior doors, bridges, trailer decking, and high-end flooring.

North Mississippi has many species of both groups. Common red oaks include southern red, water, willow, cherrybark, and shumard oaks. Common white oaks include white oak, post oak, swamp chestnut, and overcup oak.

How Does Wood Dry?

When lumber is sawn from fresh cut logs, they hold an enormous amount of water, and need to be dried before using. Failure to dry your wood first can result in cracking, warping, mildew and bugs. Boards are primarily dried by stacking them with sticks, spaced every 16” or so, in such a way as to allow wind to move over their surface. The process of warm air moving through the stickered stacks of lumber is how wood is dried. First, we stack wood outside, to air-dry, as opposed to putting it directly into the kiln. This is because ideally you want to dry wood out as slowly as possible to avoid defects that come with rapid drying, such as checking and case-hardening, which weakens the wood. Lumber should be left to air-dry until it has reached a minimum moisture content (MC) of 20% or so. However, properly useable air-dry wood has an MC closer to 12%. But, once the boards have reached 20% MC, they are safe to move into the kiln. The dehumidification kiln replicates that same natural drying process of warm air moving over the stacks of lumber, but multiplies it. The kiln itself is simply a well-insulated room designed to retain much of the heat it generates. There are some fans in the ceiling and an industrial dehumidifier with a heater, which removes the water, drawn out of the lumber, from the room. This kiln process actually removes water from the cell walls of the wood, which is not possible through air-drying. The process also kills any bugs that may be present, which is what we call a sterilization cycle. All wood sold at a lumber yard goes through some kind of process like this before it’s sold.

How Do We Source Our Logs?

It all begins with an idea.

We get our logs from you! Most of our logs are from trees that have come down in a storm, or needed to be removed from a property for one reason or another. We don’t typically buy logs from larger logging companies, as we have been able to rely on a small local economy of arborists who bring logs to us for cash, rather than dumping them in a ditch or burning them. Relying on this community gives us a much wider range of species to deal with, which allows us to provide what we like to call Domestic Exotics!